About us

About us

We develop and produce

lifting and lashing technology of the highest quality - made in Germany

Everything from a single source: Development, production, trade. We are one of the leading manufacturers of lifting and lashing equipment in Europe. Our portfolio includes the development, production and trade of lashing straps, lifting slings, round slings, sling chains, hoists and the suitable accessories. Our products ensure maximum safety wherever heavy loads have to be lifted and transported: in construction, industry and transport.

Founded in 2002

Our family-run business, founded in 2002, is located in Großröhrsdorf, Saxony.

2021 revenue: 9.5 million

SHZ stands for continuous and sustainable growth. Since 2008, we have more than tripled our sales from 3 million to 9.5 million.

75 + employees

We focus on teamwork, dialogue and networking and promoting the personal development of our employees. Because they are the basis of our joint SHZ success.

340 years of experience

Strap and belt weaving has a tradition of over 340 years in Großröhrsdorf.

100 % family

SHZ is a 100% owner-managed company. Flat hierarchies and independence from investors favor fast, demand-driven action.

50 + countries

SHZ is one of the leading suppliers of lifting and lashing technology - made in Germany. Our products are sold in more than 50 countries worldwide.

About us

‘Our high vertical range of manufacture and the many years of experience of our employees ensure that we can also implement individual customer requirements and even complete new product developments for our customers without any problems - and in the shortest possible time.’

– Günter Böhme, Managing Director of SHZ GmbH

About us

Highest product

quality made in Germany

Our SHZ lashing straps, lifting straps and round slings are still produced in Germany and meets the requirements of the European standards EN 12195-2 and EN 1492- 1/-2. We process around 7,000,000 meters of webbing per year. In doing so, we focus on demanding Technology and well thought-out processes to ensure consistently high product quality.

SHZ GmbH

Großröhrsdorf

About us

SHZ stands for the highest level of quality and safety

- Company headquarters and production site Großröhrsdorf

- Various NC sewing machines and heavy sewing machines

- Round sling machine up to 60 t/20 m NL

- Printing machine up to 120 mm strap width

- Own testing machine (tearing machine)

- Manufacturing in 2 shifts

About us

Our SHZ

image film

About us

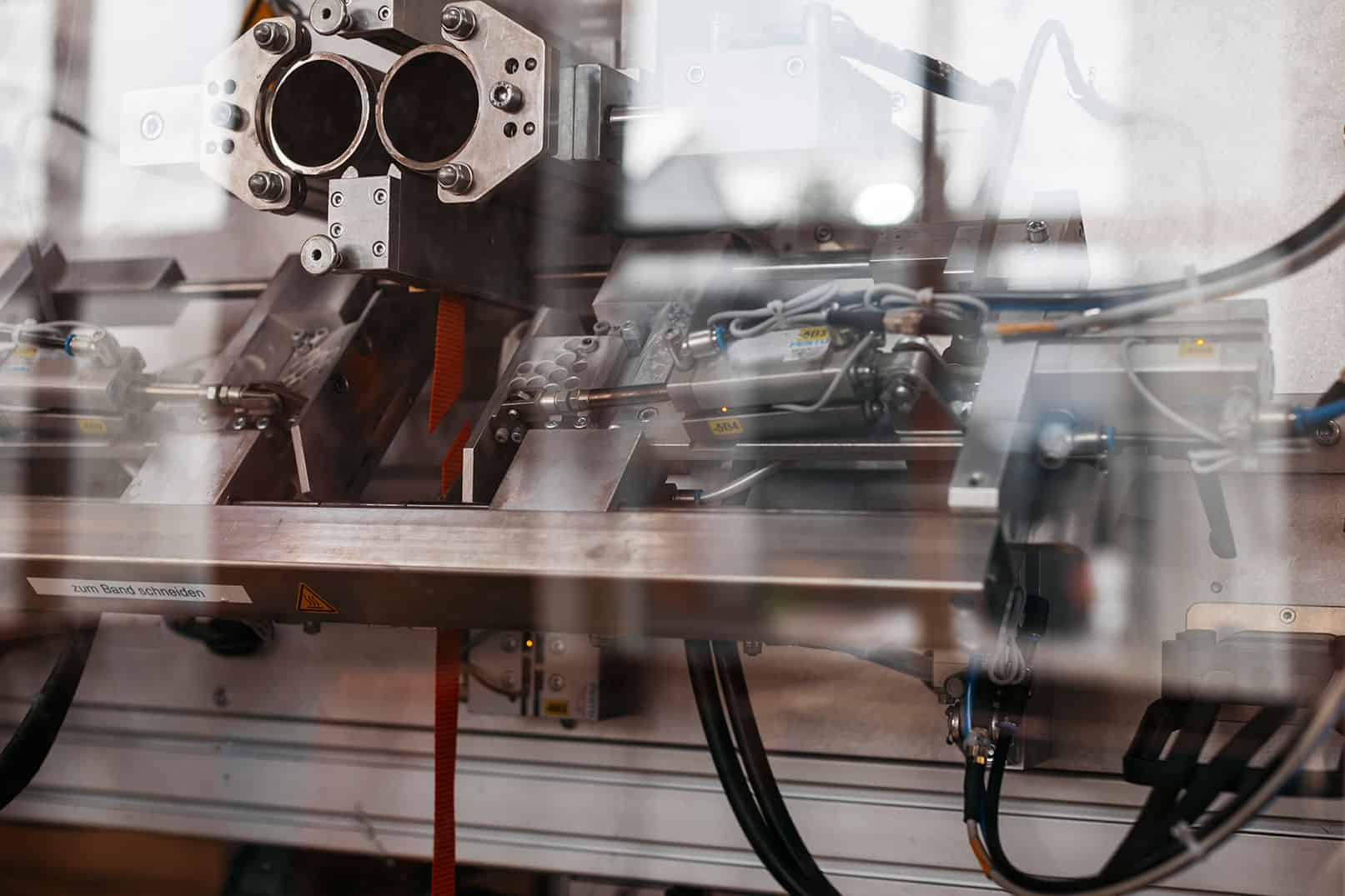

Highly modern

and automated production lines

The SHZ quality management system according to DIN ISO 9001 ensures well thought-out and efficient processes. Consistently high product quality of our lashing straps and lifting slings is guaranteed by high-performance automatic sewing machines, state-of-the-art sewing machines and our multi-stage SHZ quality assurance system.

Everything from a single source: Auxiliaries & accessories

As a full-range supplier, we also provide you with a wide selection of tools (lashing calculators, descriptions) and accessories (anti-slip mats, edge and fire protection).

Production according to European standards

SHZ lashings are manufactured exclusively in accordance with the currently valid EN 12195-2 standard.

Individualization of your products

We offer a wide range of customisation options: We realize strap colours, prints or labels according to your individual customer request.

Flexible belt widths and pretensioning forces

Strip widths from 25 to 75 mm. Prestressing forces up to 20,000 daN (tons).

About us

Product tests above

standard requirements in the inhouse test laboratory

All SHZ products undergo an intensive quality assurance process before they leave the factory in Großröhrsdorf. They are regularly tested in our in-house test laboratory according to our SHZ test guidelines. These testing guidelines, which we have set ourselves, clearly exceed the prescribed level of the valid EN standards. In addition to comprehensive product testing as part of quality assurance, we also offer our customers comprehensive service. This includes the inspection, maintenance and repair of textile slings, chains and hoists.

about us

'We attach great importance to the high quality of our products so that our customers can work safely. This is also what our SHZ claim “Moving big things. Savely.” stands for.'

– Matthias Böhme, Managing Director of SHZ GmbH

About us

Short delivery times thanks to 1.2 million in investments in new warehouse

In order to make us less dependent on foreign suppliers and to be able to offer our customers even shorter delivery times in the future, we invested EUR 1.2 million in a new warehouse in the spring of 2021. This will allow us to offer our customers even better services in the future - through significantly shorter production and delivery times. In addition, this also increases our delivery reliability. A criterion that has become much more important for many customers in Corona times.

About us

Chronology –

Our company history at a glance

Largest centre of strap and belt weaving in Germany

In the mid 19th century, Großröhrsdorf was one of the most important centres of German ribbon and strap weaving. 32 + factories | 10,000 + ribbon looms

Kombinat Bandtex

During the German partition, the Großröhrsdorf strap production and processing was continued by the Kombinat Bandtex. With German unification, it came to a standstill.

Establishment of SHZ GmbH

Founded in February 2002 by four partners, two of whom are still active in the company today. September 2002: Relocation to a larger hall and thus quadrupling of the production area.

On course for growth: 25 - 30 percent growth per year

Continuous growth far above the industry average promotes steady investment: Expansion of machinery, enlargement of parking areas, expansion of office space, construction of a changing room, new construction of a dining room. 2004: more than 1 million sales and 16 employees for the first time.

Moving into the new headquarters - and further growth

Hiring of the 40th employee and acquisition of a 50t inspection machine. New construction of the warehouse. 2010: more than 40 employees. 2012: tenth anniversary of the company.

Increased productivity through automation

Commissioning of the new production line for 50mm lashing straps. New construction of the warehouse (400 sqm, expandable to 1,200 sqm).

Expansion of production capacities

Construction of an extension to expand production capacity due to sustained high demand. Further investments in automation technology: Production line for round slings and fully automatic production line for endless slings production.

1.2 million investment in new warehouse

700 sqm of more storage space. Guaranteed supply security during the Corona pandemic. Shortened delivery times. More than 75 employees and EUR 9 million in turnover.

We are here for you!

You can reach us by phone from

Mon – Fri 8 am – 5 pm at:

Alternatively, you can also contact us at any time

using our contact form: