Lashing straps

Products

Quality when

it matters

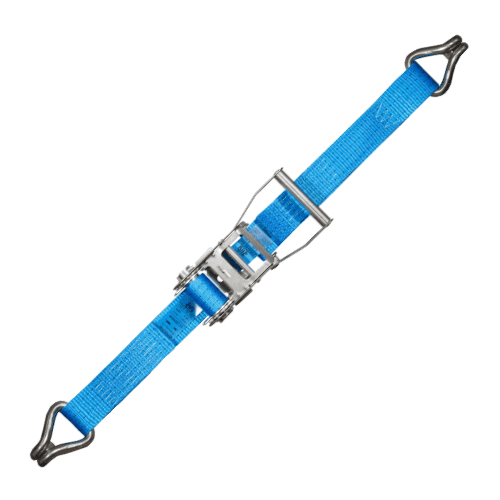

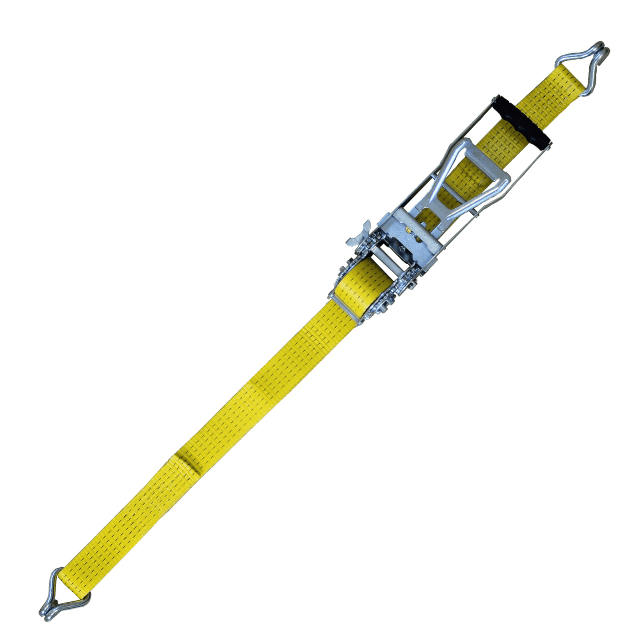

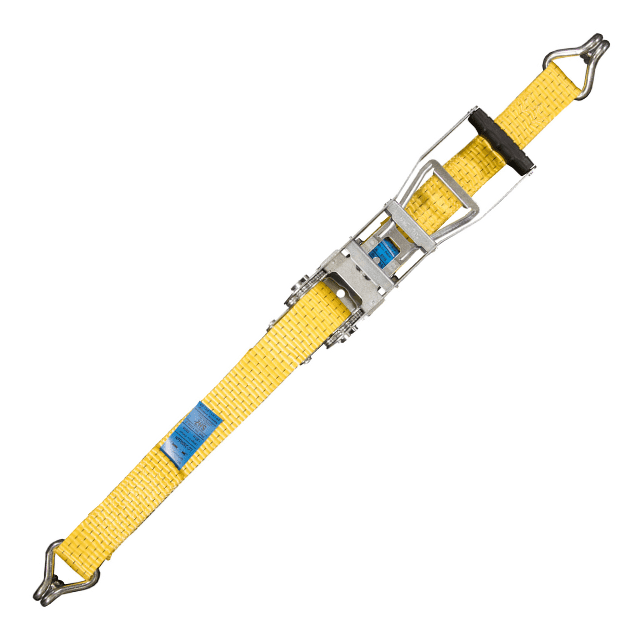

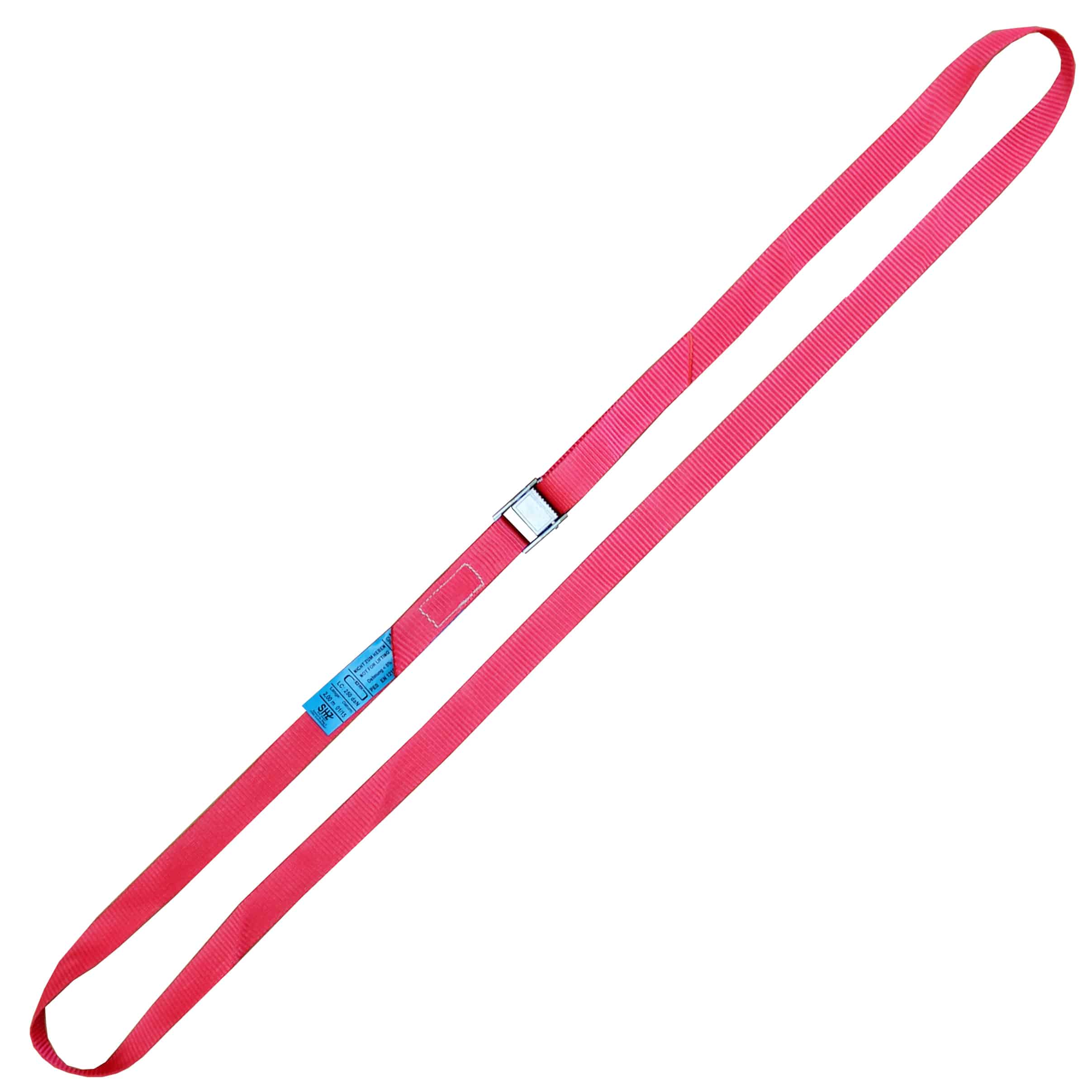

Thanks to our in-house production, we can offer you a large variety of lashing straps. All SHZ lashing systems are manufactured in accordance with the EN 12195-2 standard. In addition to our standard products, we also produce more sophisticated lashing systems in various lengths - with different ratchets, clamp locks and a large selection of different hooks. With our lashing strap configurator, you can individually put together your desired lashing strap.

Products

Our lashing straps

portfolio

Products

Important

information

Belt widths 25 mm to 75 mm

LC 125 – 10,000 daN

Lengths can be produced exactly according to your requirements.

1- or 2-part with different hooks (Double J-hook, U-hook, snap hook etc.)

To ensure that you get through the next inspection safely, you should check your lashing straps before each use. The lashing straps are to be taken out of service immediately if one of the following damages is found:

- Damage to the webbing that affects more than 10 percent of the cross-section or the width of the webbing

- Deformation, hardening, fusion or softening of the belt strap due to the action of heat or chemicals. As a preventive safety measure, lashing straps should always be taken out of service after contact with chemicals.

- Cracks, notches, deformations or embrittlement of the hardware components or ratchets

- heavy wear on fittings or ratchets

- missing or illegible labels

Products

Possibilities of

individualization

We would also be happy to print your text or logo on the lashing strap.

- Text length as desired

- The text is always black

- Long logos and texts are also possible

- For both small and large quantities

- Any distance between prints is possible

- In the belt colors purple, green, yellow, gray, red, brown, blue, orange

- Individual belt widths and lengths possible

Products

Practical accessories

for lashing straps

We would also be happy to supply you with the right accessories for your lashing straps.

We are here for you!

You can reach us by phone from

Mon – Fri 8 am – 5 pm at:

Alternatively, you can contact us at any time

reach via our contact form:

Lashing straps - Important aids for securing loads

Lashing straps are load securing devices for connecting and lashing objects. They consist of textile fibers such as polyester and are subject to the specifications of the European standard DIN EN 12195-2. Wherever loads are transported, you are well advised to use SHZ products. Discover our product range for load securing and use the appropriate services from advice to our lashing strap configurator. In addition to our lashing straps, you can also get load securing accessories.

Lashing straps from SHZ

In our factory in Großröhrsdorf/Saxony, around 7,000,000 meters of webbing are processed into lashing straps and other load securing products and slings every year. We rely on sophisticated technology and state-of-the-art processes. A high level of vertical integration and the many years of experience of our employees ensure that we can implement almost any customer request.

Highest product quality - made in Germany

SHZ lashing straps are manufactured according to the EN 12195-2 standard. In all production steps – from adhesive tape printing to cutting to automatic sewing – we rely on the most modern production facilities. All products go through an intensive quality assurance process before they leave the factory in Großröhrsdorf. We test all products regularly in our own test laboratory according to our SHZ test guidelines. These clearly exceed the prescribed dimensions according to the applicable EN standards. Our certified quality management system according to DIN ISO 9001 also ensures consistent product quality.