Lashing strap quality put to the test

High quality or inferior?

This is how you can check the quality of your lashing straps yourself - in 3 simple steps

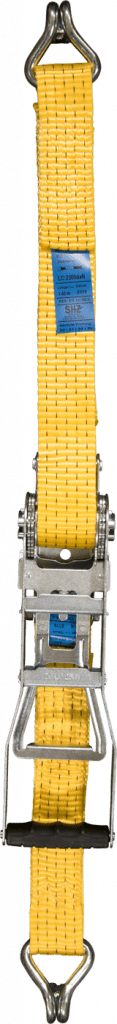

In order to be able to move heavy loads safely, lashing straps are used during transport. But lashing straps are not just lashing straps. Many inferior products from the Far East are “flooding” the market and can lead to safety risks when transporting goods – and in the worst case even endanger human life. The following points can help you to distinguish high-quality lashing straps from renowned manufacturers from cheap imports when buying lashing straps. Use a few key points to check for yourself whether your lashing straps have been manufactured in compliance with the EN 12195-2 standard:

1. Are all important information on the label present?

First, it is important to check that all the required information is on the label. Click on the orange dots to find out more.

manufacturer and date of manufacture

Standard according to which the lashing strap was produced

Material from which the belt is made

- PES (polyester) = blue label

- PA (polyamide) = green label

- PP (polypropylene) = brown label

traceability code

Elongation under the highest allowable force (LC)

Forces are for straight pull

Decisive for direct lashing: correct specification of the lashing capacity LC value

LC value (Lashing Capacity) = the highest permissible force that the belt can withstand without tearing in a straight pull

- wrong would be: LC 2500/5000 daN (5 tons)

- correct is: LC 2500 daN (direct) / 5000 daN (id converter)

Decisive for tie-down lashing: Correct specification of the standard pre-tensioning force (STF value)

The STF value (standard tension force) stands for the maximum tension force that is possible when lashing down.

- SHF = hand strength

- STF = preload force with manual force

Both values are given in decanewtons (daN). An STF value of 500 daN, for example, corresponds approximately to a tensioning force of 500 kg with which the ratchet pretensions the belt.

Lashing strap length

GS mark = voluntary information, not a reliable indicator of high quality lashing straps

checklist

Lashing straps must be checked for damage before each use by the user and once a year by a qualified person. With SHZ lashing straps, you can mark the test directly on the label.

DANGER: A GS mark is not always a reliable indicator of high quality lashing straps

A GS mark is an additional voluntary test mark and certifies product testing and production monitoring by an independent testing and certification body (e.g. TÜV, DGUV). However, it is not always a reliable indicator of high quality lashing straps. During an inspection by the FSA association in October 2018, 36 lashing straps were tested. 17 lashing straps showed significant defects, 14 of which carried a GS mark.

Web tip: https://www.fsa-verband.de/fsa-deckt-gravierende-maengel-bei-zurrgurten-auf.html

In addition, GS marks are sometimes forged or not printed correctly . However, the authenticity of a GS mark can be checked via databases at the responsible certification bodies, e.g. e.g.:

Tip:

A CE mark must not be shown.

= Indication of faulty manufacture

Since lashing straps are NOT covered by the Machinery Directive, they do not require CE marking.

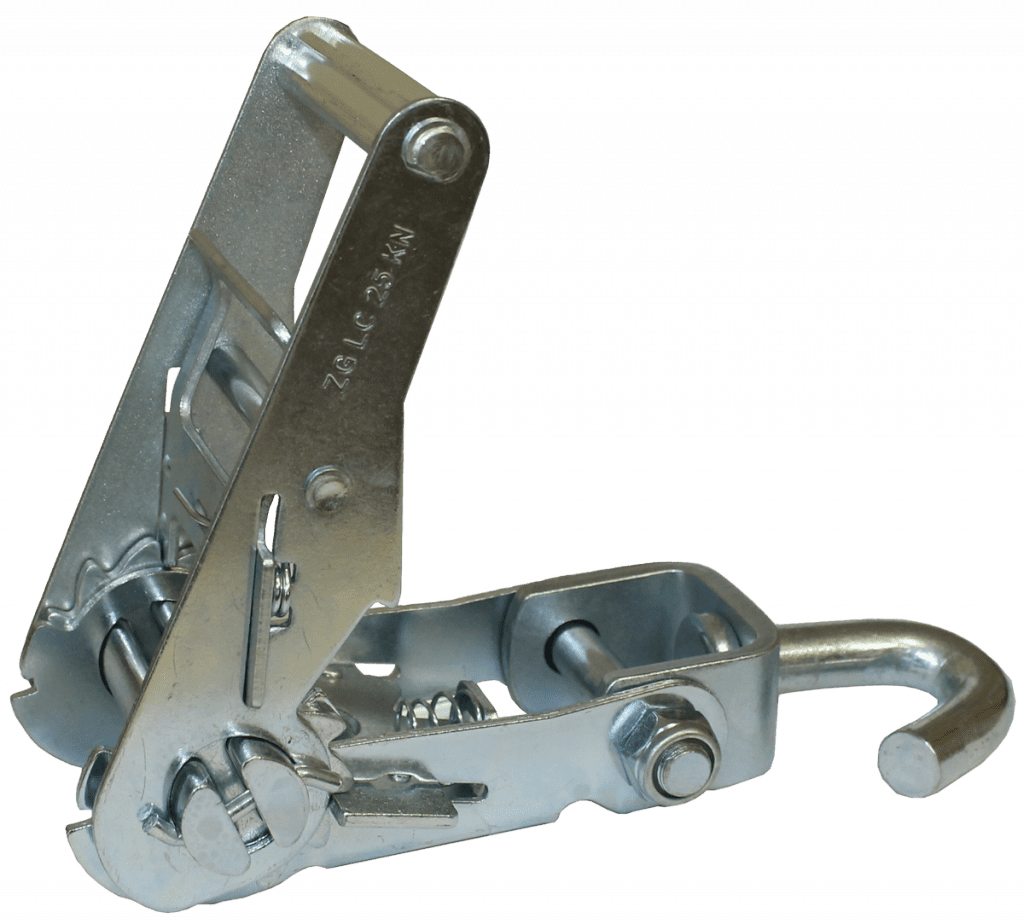

2. Are the fittings and ratchets properly marked?

Fittings and ratchets have to be marked with:

- Information about the manufacturer (name or symbol)

- LC value

User information should be supplied with each lashing strap.

Example of user information:

- Check the lashing before each use

- Do not use if the belt or tensioner is damaged

- Note that the necessary lashing capacity (LC) and pre-tensioning force is used in each case.

- Use the necessary number of lashings according to the load.

- In the case of sharp edges, edge protection may only be used for lashing.

- Do not knot the lashing strap / permissible operating temperature: -40 °C to +100 °C

- Please never use for lifting.

3. Further test criteria:

- Are instructions for use provided for the lashing strap?

- Is it a well-known supplier/manufacturer with sufficient experience?

- Does the supplier/manufacturer have a quality management system , e.g. B. according to DIN ISO 9001?

- Is the supplier/manufacturer able to carry out product tests ?

The above test criteria should support you in an initial visual quality check of your lashing straps. However, a manufacturer test according to EN12195-2 includes significantly more points. SHZ offers you this comprehensive testing service in our in-house testing laboratory .

All information without guarantee and claim to completeness.